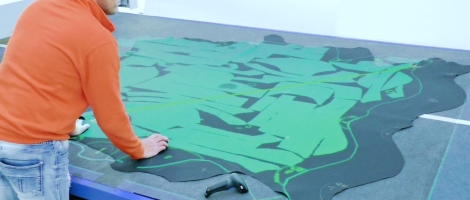

Elitron PlazaThe automatic cutting systems in the Plaza Series are specifically designed for furniture, upholstery, apparel and automotive. These cutting systems can work on many different materials by automatically choosing the most appropriate tool available on the Multi-Tool Cutting Head. Thanks to the great flexibility of the PLAZA Series, manufacturers and be real innovators. The Video Projection system shows in real time the manual nesting of the shapes thus increasing the overall material yield and easing the job of the operator. The video projection system can even be used to help the operator collecting the processed materials. The operator can configure the working area of any Plaza Series in several sections, for alternate processing (placement, cutting, discharge), thus optimising job times.

PLAZA cutting systems are able to cut a wide range of materials such as: |

-

Consumables

-

Sun Protection

- Curtain Production

- Matic M21 Cutting Machine

- EOS Curtain sewing automation

- SEWING-Matic Nyx Overlock sewing system

- SEWING-Matic NYX Ultimate Curtain Sewing System

- SEWING-Matic Nyx Compact

- SEWING- Matic Nyx Top Tape

- SEWING-Matic Nyx Roman

- CUTTING- Matic Olympo Curtains

- CUTTING- Matic Helios Plus Laser

- CUTTING- Matic Flexicut Linear Cutter

- IRONING-Aura Ironing System

- HANDLING-Matic Inspector

- CUTTING-Matic Sonomatic

- STORAGE Matic Atlas H

- Plastgrommet Curtain Station

- Olympo Curtain Inspection

- Printers

-

Roll Cut

-

Cutting

- Digital

- Elitron Spark C

- Elitron Spark F

- Elitron Kombo SD+

- Elitron Kombo TH

- Elitron Kombo SDC+ 3.2

- Elitron Klick Print Management Software

- Elitron Seeker System explained

- Elitron Custom Cutting details

- Matic Flexicut

- Flexa Miura

- Flexa Miura Plus

- Flexa Miura Plus HD

- Flexa Miura II 1650 Wallpaper

- Flexa Extrim

- Flexa Katana

-

Laminators

- CWT Applicator Tables

- OUR GUIDE TO Buying a CWT Flatbed Applicator, Lamination Table or Sign Applicator

- CWT ADVANTAGE FLATBED APPLICATOR TABLE

- CWT REGULAR FLATBED APPLICATOR TABLE

- CWT PREMIUM FLATBED APPLICATOR TABLE

- CWT Linear Cutter

- CWT Linear Cutter Pro

- Traffic Signs

- Cutting Mat Clear Blue Frosted

- Cutting Mat Clear Blue Standard

- Cutting Mat Anti-Static

- CWT Original Cutting Mats

-

Finishing

- Eyelet Machines

- Hand Presses for Eyelets

- Plastrommet Semi-automatic Queen & SpeedQueen

- Plastgrommet Crossover

- Plastgrommet Evolution Automatic eyeleter

- Plastgrommet Autocross Automatic

- Plastgrommet Multipress Automatic

- Plastgrommet Finishing Station

- Plastgrommet Roll to Roll Range

- Plastgrommet All in One

- Plastgrommet TexWiz

- Plastgrommet Clear Plastic Recyclable Eyelets

- Forsstrom HF eyelet

- Sewing Machines

- Matic CRONOS GO

- Matic CRONOS SEWING SYSTEM

- Matic CRONOS 4.0

- Matic Nyx Overlock

- Matic Nyx Ultimate Curtain Sewing System

- Matic ORION SEWING SYSTEM

- Matic Hercules Awning Sewing System

- Matic Nyx Compact

- Matic Nyx Top Tape Sewing System

- Matic Nyx Roman

- Recyclable Thread

- Recyclable Keder SRK

- Cotton Cones Dual purpose

- Cotton bonded nylon

- White Keder

- Translucent Blue Keder

- Self Adhesive Recyclable

- Silicon Keder

- Hammer In Keder Silver

- Hammer in Keder Clear

-

Racks & Lifters

- Plastgrommet Media Handling

- PLASTGrommet Bull Rack 1620

- Plastgrommet BullRack MAX

- PLASTGrommet BullRack Cutter

- PLASTGrommet BullRack XXL

- PLASTGrommet Jumbo Rolls Transporter

- PLASTGrommet Mobile 12

- PLASTGrommet Mobile 16

- PLASTGrommet Easy Rack

- PLASTGrommet Wallrack

- PLASTGrommet Multi Rack

- PLASTGrommet Rolling Rack

- PLASTGrommet SwivelRack

- PLASTgrommet Roll Clips

- PLASTGrommet Compact Lifter

- PLASTGrommet Compact e- Lifter Lite

- PLASTgommet e-lifter Pro

- PlastGrommet RollMax Lifter

- PlastGrommet RollMax e- lifter

- PlastGrommet Jumbo Floor Rack

- PlastGrommet Jumbo WallRack

- Used & Ex-Dem